•. Fully Automatic line

•. Line Design, Project Management, Process Engineering, Supply Chain management, Future roadmap etc.

•. Minimum operator requirement.

•. Can produce all new generation solar modules.

•. Upgradable to upcoming SiC technologies like TopCon, Perc, Bifacial, HJT, TOPCoRE etc.

•. Complete turnkey solution.

•. Technology and manufacturing training.

•. Installation & Commissioning, Troubleshooting, Operator training.

•. Raw material sourcing / procurement.

•. Certification support.

•. Service support.

•. MES integration.

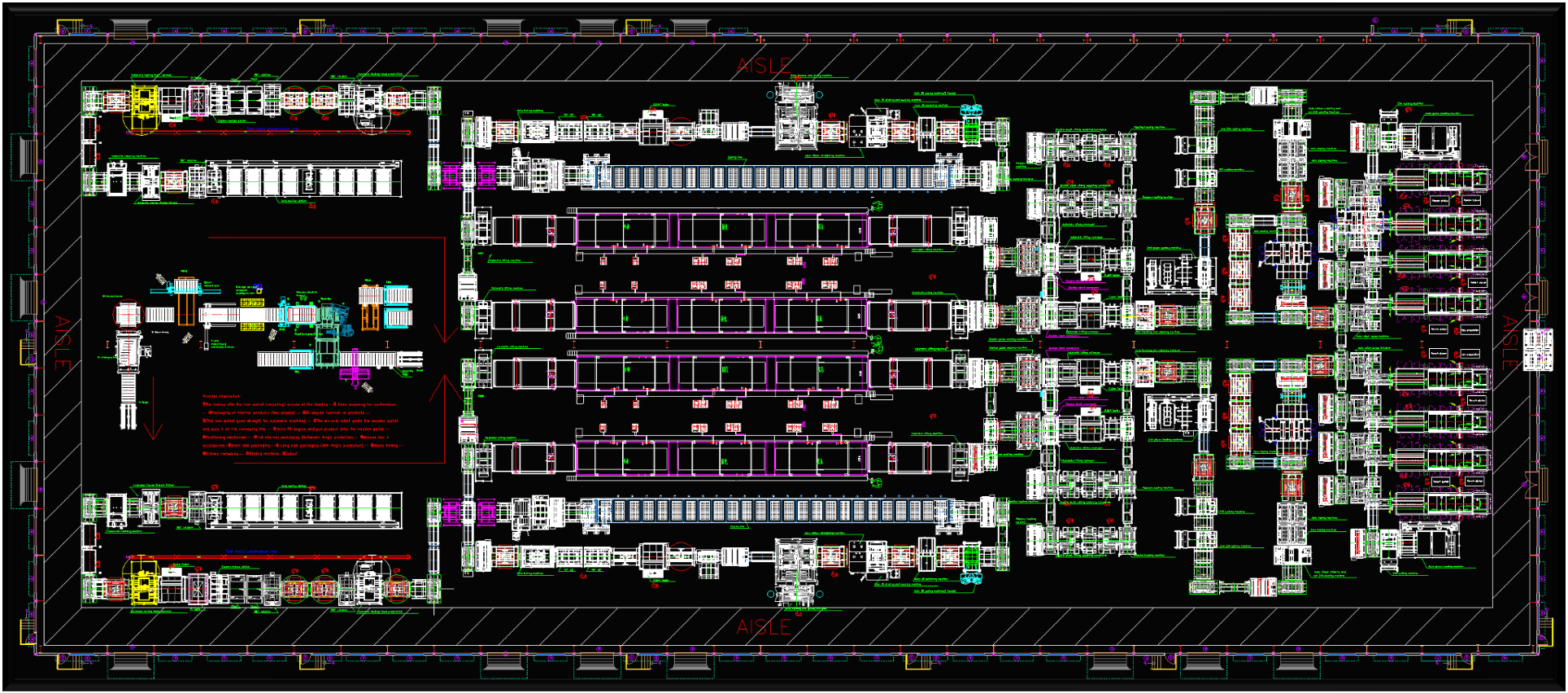

Standard line configuration:

- Auto Glass Loading system

- Auto 1st EVA cut and place

- Auto Tabber Stringer

- Auto ROBOT Layup

- Auto Bussing machine

- Auto Tape sticking machine

- Auto 2nd EVA cut, punch hole and place

- Auto back sheet cut, punch hole and place

- Second glass loader for double glass module

- Auto EL and Visual testing with repair line

- Double glass sealing machine

- Automatic DOT Matrix electric heating Laminator

- Auto edge trimming system

- 90 Deg visual testing

- Auto Framing Machine

- Auto JB Gluing machine

- Auto Curing line

- Auto corner filing machine for Al frames

- Hi-Pot Tester

- Full LED IV Tester

- EL Tester

- Auto Sorting station